Hillcrest Energy Technologies has announced a significant milestone for its ZVS-enabled power modules, positioning the company to take advantage of a potential new revenue stream.

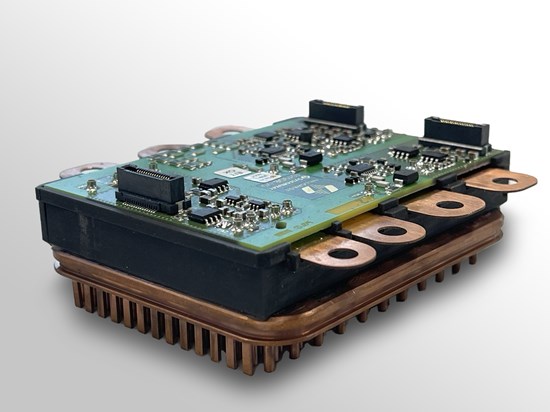

Power modules play an essential role in driving an inverter’s power-switching functions. Packaging the silicon carbide dies into a module greatly improves manufacturability, provides better thermal control, power density and reliability and results in significant cost savings when compared to the use of individual (discrete) components.

Hillcrest’s next generation EV inverter features the new ZVS-enabled power modules, delivering a substantial boost in power level and power density while being designed to facilitate high-volume manufacturing in industries like automotive. This next generation EV inverter is currently being used for testing and demonstration programs with various potential customers and partners.

James Bolen, Hillcrest’s Chief Commercialization Officer, commented: “Hillcrest’s ZVS-enabled power modules not only elevate the performance and power density of the Company’s EV inverter but they also open new avenues for standalone sales.”

Mr. Bolen continued: “With the global power module market reaching US$2.7B in 2022 with a forecasted annual growth rate of more than 11% in the coming years, this could become a valuable potential revenue stream for the Company.”

Ari Berger, Hillcrest’s Chief Technology Officer, added: “Our ZVS-enabled power modules have been designed and manufactured in-house by our team and are a testament to the combined capabilities of Hillcrest and our technology development partners at Systematec GmbH.” Berger also notes, “These capabilities are pivotal to our success, especially as we engage with a growing list of potential clients in the automotive sector.”

Hillcrest intends to design ZVS-enabled power modules to operate independently of specific application controls. This approach enables near-seamless integration into a variety of applications, from electric vehicles and aviation to grid-tied stationary applications, without the need for significant re-qualification and modification. Utilizing this approach is expected to accelerate the delivery of the power modules to the market.